Summary

Waste-to-energy solution installed to manage clinical/hazardous waste for a major NHS hospital in the UK.

- C350 Clinical Incineration Facility

- Automated Loading Systems

- Optimised Contaminated Waste disposal

- Reduces Carbon Footprint of NHS

- Dispose Of Hospital and Health Centre Waste

- Hot Water Heating Generation

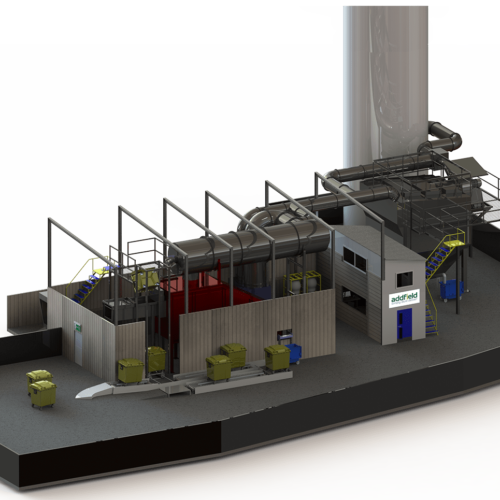

Advanced Waste To Energy Facility in the UK

This installation represents a massive investment by the world's largest healthcare provider, the NHS. Designed, manufactured, installed, commissioned and operated for the first couple of years by Addfield. This facility became the UK's most advanced clinical waste-to-energy system once completed.

This project began several years before construction even started. Extended consultations between Addfield and the Royal Wolverhampton NHS Trust began in 2015 to ensure that every element was considered and optimised for this new flagship installation. Intended to replace an old incinerator which had become ineffective and costly to operate following decades of use. The NHS requested the next generation of waste treatment, and Addfield delivered the C350 waste-to-energy solution.

A Sustainable Approach To Heating

It was installed to dispose of all the clinical waste produced daily by the hospitals' 850 active beds, all active outpatient clinics and associated health centres across the Wolverhampton Trust.

In addition to managing the waste, the system also incorporates a "waste-to-energy" component that utilises waste heat from the incineration process. This heat generates low-pressure steam directed to the hospital's boiler house. The steam is used to heat the hospital, replacing the need for fossil fuels. It reduces the hospital's carbon footprint and provides a source of clean, renewable energy. Overall, the new installation represents a significant step forward in sustainable waste management for the NHS.

This has proven an incredible success. Disposing of 350kg of hazardous waste every hour and in operation 24 hours a day, the facility makes a dramatic impact on the hospital's environmental aspirations of being carbon neutral.

Expert Departments Working together

The installation at the NHS New Cross hospital was made possible thanks to a collaboration of our team of in-house designers, welders, fabricators, refractory masons, electrical engineers, combustion engineers and project management staff. The team worked together to incorporate the latest advances in engineering and design, resulting in a clinical waste disposal system considered the most advanced in the UK.

The waste is loaded into the system using a bin conveyance system, which can accept up to ten bins simultaneously. The system automatically scans the bin barcodes, weighs the bins, and conveys the waste to the primary incineration chamber. The whole process is automated, ensuring efficiency and accuracy. The advanced technology in the system allows for the safe and secure disposal of clinical waste while also generating clean, renewable energy.

The primary combustion chamber of the waste-to-energy system operates using a stepped hearth principle, which allows for continuous loading and de-ashing. Waste enters the chamber at the highest point and is pushed through the stepped staging area by hydraulically powered pushers, undergoing intense temperatures as it moves. Once the waste has been thoroughly treated, it is pushed into the de-ashing zone and extracted by a fully automatic de-ashing system for safe disposal.

Automatic Waste Tracking And Management

Throughout the entire waste-to-energy process, a "Waste Quantity Tracking" system is in operation, continuously monitoring and confirming the amount of waste being loaded and processed by the machine. The system requires loading every 10-15 minutes, but the conveyance system reduces the need for operator attendance and labour by only requiring attendance approximately every two and a half hours. This throughput management provides clear visual indications to prevent untimely unloading of the system, ensuring optimal efficiency and preventing operator error from overloading.

The system also uses barcode scanning to provide asset management and tracking, allowing the operator to track the origin of the waste. This information is used to prepare the plant for incoming waste and its potential calorific value, enabling the machine to automatically adjust its settings for the most economical and efficient thermal treatment process. The combination of advanced technology and careful management ensures that the waste-to-energy system operates at maximum efficiency, providing a sustainable solution for clinical waste disposal.

This Project Has Included:

Persistent Support Throughout

- Turn-key supply

- Design – engineering – manufacturing – installation – commissioning – training – proving – handover

- Compliant to the Waste Incineration Directive EC 2000/76 and Industrial Emission Directors IED 2010/75/EU

- Automatic loading bin tipper system

- Automatic de-ashing

- Energy recovery system

- De-Nox kit installed

- Sorbent reagents used for further neutralisation

- Dry ceramic filter system

- Full MCERT’s accredited 24/7 online continuous emission monitoring

The waste-to-energy system at the NHS New Cross hospital was designed, engineered, and manufactured in Great Britain. It was installed, commissioned, and handed over by a team of experienced professionals. The system complies with the Waste Incineration Directive EC 2000/76 and Industrial Emission Directors IED 2010/75/EU, ensuring that it meets all necessary regulations and standards.

The system features several advanced technologies and features, including an automatic loading bin tipper system, automatic de-ashing, an energy recovery system, and a De-Nox kit for emissions control. Sorbent reagents are also used to neutralise waste further, and the system is equipped with a dry ceramic filter system. Additionally, the system has full MCERT's accredited 24/7 online continuous emission monitoring to ensure that it operates safely and efficiently at all times.

The sustainable solution has a design life of 20+ years, and the NHS site is located 15 miles from Addfields factory in Staffordshire. This waste-to-energy system represents a significant step forward in sustainable waste management and clean, renewable energy generation.

To read the experience of the NHS in using this installation after three years Click Here